Product Catalogue

Explore our comprehensive range of steam system components and water treatment solutions

VALSTEAM ADCA Products

Precision European engineering for optimal steam system performance

As the official West African representative agency for VALSTEAM ADCA, we offer their complete range of high-quality steam system products. Below you'll find our comprehensive product catalogue.

Steam Traps

One of the widest ranges of steam traps in the market with standard to custom solutions providing the highest efficiency on your steam system.

Thermodynamic Steam Traps

DT40R

Compact design for moderate capacities

DT42/2

For higher capacity applications

DT46R

Robust construction for demanding conditions

Float and Thermostatic Steam Traps

SG IRON

Spheroidal graphite iron construction

CARBON STEEL

For high pressure applications

STAINLESS STEEL

Corrosion resistant for harsh environments

FABRICATED STEEL

Custom solutions for specific needs

Inverted Bucket Steam Traps

IB12

General purpose robust and versatile

IB812

For higher capacity applications

IB30

General purpose applications

IB36

Low to high pressure applications

Thermostatic Steam Traps

TH13A

Compact design for various equipment

TH22

Balanced pressure thermostatic

TH23

For process equipment

TH21

For various process applications

Bimetallic Steam Traps

BM20

Simple and robust for heat recovery

BM24

For steam process applications

BM32

High capacity bimetallic trap

BM87

Robust and efficient design

BM88

For high pressure superheated steam

BM89

High pressure applications

BM90

Robust and efficient design

BSS20

Compact design for air venting

BM-HC

For high load applications

Universal Steam Traps and Connectors

UCN

Universal connector system

UCN9

Complete and efficient design

UCON

High-performance offerings

UD08

Frequent tropical storm applications

UYEU

Commercial transport services

Universal Steam Traps and Connectors (Four-Bolt)

UCX90

Four-bolt flange connector

UBS90

Bimetallic steam trap for UCX90

Complementary Equipment

CDV32

Condensate drain valve

DF

Noise diffuser

BDV

Blowdown valve

HVV

Hand-vent valve

AFE

Anti-freeze device

Pressure Regulators

High-quality pressure reducing, sustaining, and blanketing valves for steam, air, water and other gases/liquids.

Pressure Reducing Valves

PRV25

Direct acting for steam, air, water and other gases/liquids

RP45

Single seated, bellows sealed without auxiliary energy

RPW45B

Diaphragm sensing for water, air and other liquids/gases

PRV57

Pilot operated for sensitive and accurate control

PRV47

Pilot operated for industrial pressure reducing stations

P7

Direct-acting, spring-loaded diaphragm sensing

P20D

Direct acting with balanced plug for compressed air and water

P20DS

For general purpose applications with low flow and high temperatures

P20P

Piston sensing for instrumentation and industrial equipment

PRV30

Diaphragm sensing with balanced plug for compressed air and water

PRV31

Piston sensing with balanced plug for compressed air and water

PRV41

Piston sensing for instrumentation and high pressure applications

Pressure Sustaining Valves

PS46

Single seated, bellows sealed without auxiliary energy

PSW46B

Diaphragm or piston sensing proportional controllers

PS47

Pilot operated for maintaining upstream pressure

PS4

Direct acting, spring-loaded diaphragm sensing

Blanketing Valves

BKR12

Tank blanketing valves for storage systems

BKV12

Tank blanketing valves for explosion protection

Pressure Reducing Stations

RP45TW

Parallel valve system for significant consumption variation

Control Valves

Precision control valves for process engineering and industrial applications with pneumatic, hydraulic, or electric actuators.

Two-Way Control Valves

Y162

Single seated, two-way globe control valves

Y362

For applications with erosion, cavitation or flashing

PY15

Pneumatic cutoff globe valves with diaphragm actuator

PPV15

Pneumatic cutoff globe valves with piston actuator

PAV21

Pneumatic angle and gate valves with piston actuators

EY15

Electric cutoff globe valves with electric actuator

Three-Way Control Valves

V303

Three-way globe control valves for mixing and diverting

V253

Three-way globe valves for general service applications

PV403

Three-way valve body for mixing service

Valves for Special Applications

VPA26/2

Blowdown valves for steam boilers

VPC26

TDS control applications in steam boilers

OVF40

Overflow valves for closed loop systems

Pneumatic and Electric Linear Actuators

PAR - PARF

Pneumatic multi-spring actuators with rolling diaphragm

PARM - PAMM

Pneumatic multi-spring actuators for modulating services

EL

Electric linear actuator for modulating duty

ELS

Electric linear actuator for control valves

ELK

Electric linear actuator with spring-driven fail-safe

MAH

Manual linear actuators with hand-wheel

Self-Acting Temperature Control Valves

TR

Direct-acting temperature control valves

TR25/R

Temperature control valves for cooling systems

Instrumentation

BCS220

Blowdown controller for steam boilers

PCSI

Pressure transmitters for industrial applications

SPS21

Conductivity probe for steam applications

SPS33

Conductivity probe for boiler water measurement

UD-720

Programmable digital panel display

UC-820

Digital universal controller for industrial processes

PCLS

Signal converter from analog to pneumatic

PPSS1

Pneumatic positioner for control valves

PPSS6

Pneumatic positioner with 4-20mA input

Pipeline Ancillaries

Comprehensive range of pipeline accessories including air vents, strainers, sight glasses, and valves for complete system protection.

Air and Gas Float Traps

SG IRON

Fully automatic ball float traps in SG iron

CARBON STEEL

Fully automatic ball float traps in carbon steel

STAINLESS STEEL

Fully automatic ball float traps in stainless steel

CAD

Compressed air automatic drain valve with timer

Automatic Air and Gas Vents for Liquid Systems

CARBON STEEL

Air and gas vents for liquid systems in carbon steel

STAINLESS STEEL

Air and gas vents for liquid systems in stainless steel

Vacuum Breakers

VB21 - VB21M

Vacuum breakers for steam heated units

VB17

Vacuum breakers for pipelines and vessels

Pipeline Strainers

IS140

Y strainers for steam, water, oil and air systems

IS116

Forged steel Y strainers

IS147

Cast iron Y strainers

IS147 (EN)

Cast steel T strainers - European standards

IS147 (ASME)

Cast steel T strainers - ASME standards

Sight Glasses

SW12

Single window sight glasses for steam trap monitoring

DW40

Double window sight glasses in carbon steel

DW12

Double window sight glasses in cast iron and stainless steel

SCKI

Sight checkers with integrated check valve function

Non-Return Valves

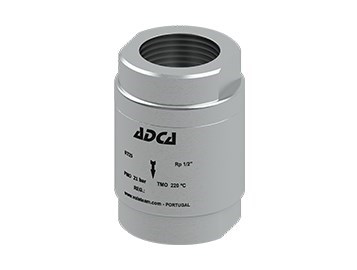

RT25

All stainless steel disc check valves

RD40

Disc check valves for steam and hot condensate

Isolation Valves

M3B

Reduced bore three-piece ball valves

M3H

Full bore three-piece ball valves

M3SH

Full bore three-piece ball valves in zinc plated carbon steel

M3W1 / MW1

Wafer type ball valves

SM1

Spring return handles for ball valves

Pressure and Level Gauges, Cocks and Siphons

NYMP

High pressure needle valves for gauge isolation

CCBB

Gauge isolation valves for instrument protection

LCC-019

Compact level gauge for pressure vessels

Special Equipment

Comprehensive range of specialized equipment including pumps, separators, heat exchangers, and boiler house equipment for complete industrial solutions.

ADCAMAT Pumps and Pump Traps

POP

Pressure Operated Pump for high-temperature liquids

POPS-K

Packaged pump units for condensate and other liquids

POP-LC

Low capacity pressure operated pump

PPT14

Automatic pump trap for condensate discharge

PPT-K (Simplex)

Packaged pump trap unit for condensate systems

ANST

Automatic pump trap for poor return line conditions

Humidity Separators

S16

Centrifugal separators for steam and compressed air

S25

Centrifugal moisture separators

SF251

Centrifugal separators with flanged connections

SH25

Horizontal centrifugal separators

Sample Coolers

SC32 / SC132

Sample coolers for boiler water analysis

SC32F / SC132F

Sample coolers with specific connection sizes

SC32B / SC132B

Sample coolers for pressurized liquid samples

SC332 - SC532

High-pressure sample coolers

Direct Steam Humidifiers

DSH

Direct steam injection humidifiers for air ducts

Steam Injectors

SI20

Low-noise direct steam injectors

SI21

Rapid heating steam injectors

SI23

Direct steam injectors for basins and vessels

Steam-Water Mixers

MX20

Steam-water mixers for instant hot water

SG20

Water-saving guns for steam-water mixers

Packaged Units/Skids

ECRU

Electric condensate recovery units

ECRUV

Vertical electric condensate recovery units

PWHU

Packaged water heating units

FRECO

Flash steam heat recovery units

ADCATHERM Heat Exchangers

STS

Steam to water shell and tube heat exchangers

STH

Shell and tube heat exchangers

STV

Steam to water shell and tube heat exchangers

PAT

Plate heat exchangers

R SERIES

Steam to water tubular heating coils

Boiler House Equipment

RV

Flash vessel for flash recovery systems

RVST

Flash vessel with specific sizing

ADC

Atmosphere deaerators for boiler feed water

TDC

Tray-type thermal deaerators

FCD

Flash condensing heads for energy efficiency

Complementary Equipment

AS

Centrifugal air and dirt separators

MLI

Magnetic level indicators

INCC

Cooling device for condensate mixing

KH

Exhaust heads for steam exhaust protection

LIPO

Condensate lifting pipes

Select a product to view details

DT40R Thermodynamic Steam Trap

The ADCA DT40R thermodynamic disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications. The insulation cover ensures a consistent operation and makes it particularly suitable for those applications where the weather conditions, such as rain and wind, may affect the normal operation. These traps have only one moving part and offer a wide operating range, without adjustment.

Stainless steel

3/8" to 1" - DN 10 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 HV-60

Flanged ASME Class 150 or 300

Socket weld (SW) ASME EN6.11

Butt weld (BW) ASME EN4.2 on request

40 bar

300 °C

Up to 740 kg/h

DT42/2 Thermodynamic Steam Trap

The ADCA DT42/2 thermodynamic disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications. These traps have only one moving part and offer a wide operating range, without adjustment.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 140 or PN-63

Flanged ASME Class 150 or 300

Socket weld (SW) ASME EN6.11

Butt weld (BW) ASME EN4.2 on request

42 bar

300 °C

Up to 1000 kg/h

DT46R Thermodynamic Steam Trap

The ADCA DT46R thermodynamic disc steam traps are compact and lightweight-easy to install traps, excellent for high pressure systems, including steam tracing applications. The insulation cover ensures a consistent operation and makes it particularly suitable for those applications where the weather conditions, such as rain and wind, may affect the normal operation. These traps have only one moving part and offer a wide operating range, without adjustment.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 HV-60, PN

Flanged ASME EN 6.5 Class 150

Socket weld (SW) ASME EN 4.0

Butt weld (BW) ASME EN 6.2 on request

40 bar

400 °C

Up to 800 kg/h

SG IRON Float and Thermostatic Steam Traps

ADCA FLT line of float and thermostatic steam traps manufactured in SG iron and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates and pressure drops, in various sizes, with different connections and multiple options to choose from.

SG Iron

Low and high-pressure applications

Wide range of flow rates and pressure drops

Various sizes available

Multiple connection options

CARBON STEEL Float and Thermostatic Steam Traps

ADCA FLT line of float and thermostatic steam traps manufactured in carbon steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates and pressure drops, in various sizes, with different connections and multiple options to choose from.

Carbon Steel

Low and high-pressure applications

Wide range of flow rates and pressure drops

Various sizes available

Multiple connection options

STAINLESS STEEL Float and Thermostatic Steam Traps

ADCA FLT line of float and thermostatic steam traps manufactured in stainless steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates and pressure drops, in various sizes, with different connections and multiple options to choose from.

Stainless Steel

Low and high-pressure applications

Wide range of flow rates and pressure drops

Various sizes available

Multiple connection options

FABRICATED STEEL Float and Thermostatic Steam Traps

ADCA FLT line of float and thermostatic steam traps manufactured in fabricated carbon steel and designed for various high capacity applications. The available models cover a wide range of flow rates in various sizes, with different connections and multiple options to choose from.

Fabricated Carbon Steel

High capacity applications

Wide range of flow rates

Various sizes available

Multiple connection options

IB12 Inverted Bucket Steam Trap

The ADCA IB12 is a series of general purpose robust and versatile inverted bucket steam traps manufactured in SG iron. These steam traps operate intermittently and are suitable for use with saturated or superheated steam. Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

SG Iron

1/2" and 3/4" - DN 15 and DN 20

Female threaded ISO 7 Rp or NPT

Flanged EN 10252 PN 16

Flanged ASME EN 6.2 Class 150

14 bar

198 °C

Up to 600 kg/h

IB812 Inverted Bucket Steam Trap

The ADCA IB812 is a series of general purpose robust and versatile inverted bucket steam traps manufactured in SG iron. These steam traps operate intermittently and are suitable for use with saturated or superheated steam. Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

SG Iron

3/4" to 1" - DN 20 to DN 25

Threaded ISO 7 Rp or NPT

14 bar

198 °C

Up to 1,000 kg/h

IB30 Inverted Bucket Steam Trap

The ADCA IB30 is a series of general purpose robust and versatile inverted bucket steam traps. These steam traps operate intermittently and are suitable for use with saturated or superheated steam. Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

Drip points, steam tracing lines, dryers, chemical and laundry equipment

Intermittent operation

Saturated or superheated steam

IB36 Inverted Bucket Steam Trap

The ADCA IB36 is a series of robust and versatile inverted bucket steam traps. These steam traps operate intermittently and are suitable for use with low to high pressure saturated or superheated steam. Typical applications include drip points, steam tracing lines, dryers, chemical and laundry equipment.

Drip points, steam tracing lines, dryers, chemical and laundry equipment

Intermittent operation

Low to high pressure saturated or superheated steam

TH13A Thermostatic Steam Trap

The ADCA TH13A series of thermostatic steam traps are specifically designed for use on process equipment such as heat exchangers, autoclaves, food, chemical and laundry equipment. Their compact design with various connections makes them suitable for all heating applications.

Brass

1/2"

Female threaded ISO 7 Rp or NPT

1.5 bar

350 °C

10 to 80 kg/h

TH22 Thermostatic Steam Trap

The ADCA TH22 series of balanced pressure thermostatic steam traps are specifically designed for use on process equipment such as autoclaves and other specialties, bottle coolers, food, chemical and laundry equipment.

Carbon steel

1/2" to 1"

Female threaded ISO 7 Rp or NPT

25 bar

230 °C

10 to 197 kg/h

TH23 Thermostatic Steam Trap

The ADCA TH23 line of thermostatic steam traps are specifically designed for use on process equipment such as heat exchangers, autoclaves, food, chemical and laundry equipment.

Heat exchangers, autoclaves, food, chemical and laundry equipment

Compact design with various connections

TH21 Thermostatic Steam Trap

The ADCA TH21 series thermostatic steam traps are specifically designed for use on process equipment such as heat exchangers, autoclaves, food, chemical and laundry equipment.

Carbon steel

1/2" - DN 15

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 25

Flanged ASME B16.5 Class 150

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

21 bar

230 °C

10 to 795 kg/h

BM20 Bimetallic Steam Trap

The ADCA BM20 series bimetallic steam traps and air eliminators are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40 or PN 63

Flanged ASME B16.5 Class 300 or 600

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

45 bar

425 °C

Up to 4100 kg/h

BM24 Bimetallic Steam Trap

The ADCA BM24 series bimetallic steam traps and air eliminators are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 100

Flanged ASME B16.5 Class 600

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

85 bar

500 °C

Up to 5800 kg/h

BM32 Bimetallic Steam Trap

The ADCA BM32 series bimetallic steam traps and air eliminators are simple and robust traps, recommended for steam process applications where condensate sensible heat can be recovered, steam tracing lines, drip points, storage tank coils, steam air venting, etc. The use of condensate sensible heat reduces steam consumption.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 160

Flanged ASME B16.5 Class 900

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

110 bar

525 °C

Up to 6500 kg/h

BM87 Bimetallic Steam Trap

The ADCA BM87 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting.

Carbon steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 250

Flanged ASME B16.5 Class 1500

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

160 bar

525 °C

Up to 4500 kg/h

BM88 Bimetallic Steam Trap

The ADCA BM88 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes.

Stainless steel

1/2"

Female threaded ISO 7 Rp or NPT

20 bar

250 °C

Up to 1120 kg/h

BM89 Bimetallic Steam Trap

The ADCA BM89 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes.

Steam tracing lines, drip points, storage tank coils, steam air venting

Designed for high pressure superheated steam lines

BM90 Bimetallic Steam Trap

The ADCA BM90 is a series of robust and efficient bimetallic steam traps and air vents. These steam traps are recommended for steam process applications where sensible heat can be recovered, such as steam tracing lines, drip points, storage tank coils and steam air venting. Specially designed for draining high pressure superheated steam lines and processes.

Steam tracing lines, drip points, storage tank coils, steam air venting

Designed for high pressure superheated steam lines

BSS20 Bimetallic Steam Trap

The ADCA BSS20 is a series of robust and efficient bimetallic steam traps and air vents. Their compact design makes them ideal for air venting applications and condensate removal in small steam consumers.

Air venting applications, condensate removal in small steam consumers

Compact design

BM-HC Bimetallic Steam Trap

The BM-HC series of bimetallic steam traps and air vents are simple and robust traps, recommended for process applications where high loads are involved. Tailor made to meet application requirements and supplied with several bimetallic regulators in order to achieve the required discharge capacity for the application in hands.

Carbon steel

1-1/2" to 5" - DN 40 to DN 125

Flanged EN 1092-1 PN 63

Flanged ASME B16.5 Class 900

Others on request

63 bar

300 °C

UCN Universal Connector

The UCN universal connector system provides a versatile solution for steam trap installations with easy maintenance access.

Stainless steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

17 bar

183 °C

UCN9 Universal Connector

The UCN9 is a complete and efficient universal connector designed to be used as an alternative to traditional installations, simplifying maintenance and reducing installation costs.

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 300

Socket weld (SW) ASME B16.11

Butt weld (BW) ASME B16.25

UCON Universal Connector

The UCON universal connector provides high-performance offerings for steam trap installations.

According to the selected pipeline connector

20 bar

240 °C

Up to 48 kg/h

UD08 Universal Steam Trap

The UD08 universal steam trap is designed for frequent tropical storm applications, comprising the pipeline built and streamlined design. These traps operate intermittently and are suitable for high-pressure saturated or superheated steam applications.

According to the selected pipeline connector

24 bar

400 °C

Up to 45 kg/h

UYEU Universal Steam Trap

The UYEU universal steam trap provides efficient transport services across various applications, increasing customer cost-effectiveness and delivering reliable performance.

According to the selected pipeline connector

10 bar

240 °C

Up to 45 kg/h

UCX90 Four-Bolt Universal Connector

The UCX series pipeline connectors are used in steam systems where a simple and economic maintenance program is desired. Typical installations are drip service on steam lines, tracing applications and small process equipment. The four-bolt flange connector allows for fast trap replacement without disturbing the pipelines. The UCX connector fits the universal four-bolt swivel connection steam traps.

Stainless steel

1/2" to 1" - DN 15 to DN 25

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 100

Flanged ASME B16.5 Class 600

Socket weld (SW) ASME B16.11

UBS90 Bimetallic Steam Trap

The UniADCA UBS90 series bimetallic steam traps and air eliminators, completely in stainless steel, are maintenance free and sealed traps. Simple and robust, they are recommended for drip service, steam tracing applications and where condensate sensible heat can be recovered. These traps fit the UCX90 four bolt universal connectors.

Stainless steel

According to the selected pipeline connector

Up to 5400 kg/h

CDV32 Condensate Drain Valve

The ADCA CDV32 condensate drain valve automatically discharges air and condensate from steam systems during start-up. A compression spring keeps the valve open when the system is not pressurized. As soon as the operating pressure reaches the closing pressure to which the CDV is set, the valve closes. If the opening pressure drops below the closing set pressure, the spring force will cause the CDV32 to open once again.

Carbon steel

1/2" and 3/4" - DN 15 and DN 20

Female threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 16

Flanged ASME B16.5 Class 150

Socket weld (SW) ASME B16.11 on request

Butt weld (BW) ASME B16.25 on request

22 bar

250 °C

Up to 700 kg/h

DF Noise Diffuser

The ADCA DF noise diffusers are designed to disperse the high-speed discharge from steam or air traps downwards for noise reduction and reducing erosion. These compact devices are typically installed downstream of intermittent steam traps, such as thermostatic or inverted bucket, which are generally associated with high-speed blast discharges. Noise reduction greater than 50% can be expected when measured at 1 meter away from the source.

Carbon steel

1/2" or 1"

Female threaded ISO 7 Rp

32 bar

250 °C

BDV Blowdown Valve

The ADCA BDV, AFE and HVV valves are designed to drain (blowdown) or vent (depressurize) pipework, steam traps, valves and others. BDV - Blowdown valves - Manual discharge of trapped condensate and generally to be used as a drain and/or depressurization valve.

Carbon steel

1/4" and 1/2"

NPT 1/4"

NPT 1/2"

Metric thread pitch

42 bar

400 °C

HVV Hand-Vent Valve

The ADCA BDV, AFE and HVV valves are designed to drain (blowdown) or vent (depressurize) pipework, steam traps, valves and others. HVV - Hand-vent valves - Venting of air traps and generally to be used as a vent or depressurization valve.

Carbon steel

1/4" and 1/2"

NPT 1/4"

NPT 1/2"

Metric thread pitch

42 bar

400 °C

AFE Anti-Freeze Device

The ADCA BDV, AFE and HVV valves are designed to drain (blowdown) or vent (depressurize) pipework, steam traps, valves and others. AFE - Anti-Freeze device - Automatic handling of condensate from steam traps, valves, pipelines and others, to prevent the condensate from freezing inside.

Carbon steel

1/4" and 1/2"

NPT 1/4"

NPT 1/2"

Metric thread pitch

42 bar

400 °C

PS46 Pressure Reducing Valve

The ADCA PRV25 is a series of direct acting pressure reducing valves designed for use on steam, compressed air, water and other gases and liquids. These regulators are suitable for reducing steam pressure at the point of use on laundry machines, dyeing, food industries, sterilizers, etc.

Carbon steel or stainless steel

1/2" to 1" - DN 15 to 25

Threaded ISO 7 Rp

Flanged EN PN 25

Flanged ASME Class 150 or 300

Up to 17 bar

Up to 210°C

0.35 to 8.6 bar

1.7 to 3.1 Kvs

RP45 Pressure Reducing Valve

The ADCA RP45 series of pressure reducing valves are single seated, bellows sealed that operate without auxiliary energy. Designed for use with steam, compressed air, and other gases compatible with the construction. These valves are particularly suitable for reducing steam pressure in all energy and process systems where pressures must be kept under control.

SG Iron, carbon steel or stainless steel

DN 50 to DN 100

Flanged EN 1092-1 PN 16 or PN 40

Up to 40 bar

130°C

0.2 to 18 bar

26.5 to 129.5 Kvs (m³/h)

RPW45B Pressure Reducing Valve

The ADCA RPW45B series of pressure reducing valves are single seated, diaphragm sensing proportional controllers that operate without auxiliary energy. Designed for use with water, compressed air and other liquids and gases compatible with the construction.

Carbon steel or stainless steel

DN 15 to DN 100

Flanged EN 1092-1 PN 16 or PN 40

28 bar

250°C

0.07 to 17 bar

PRV57 Pressure Reducing Valve

The ADCA PRV57 pilot operated pressure reducing valves are designed for use with steam, compressed air, nitrogen and other gases compatible with the construction materials. The PRV57 can be installed in pressure reducing stations throughout all industries, and provide sensitive and accurate control even when inlet pressure fluctuations or relevant flow variations occur.

Carbon steel or stainless steel

1/2" to 2" - DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN PN 40

Flanged ASME Class 150 or 300

Socket Weld (SW) ASME B16.11

28 bar

250°C

0.07 to 17 bar

PRV47 Pressure Reducing Valve

The ADCA PRV47 pilot operated pressure reducing valves are designed for use with steam, compressed air, nitrogen and other gases compatible with the construction materials. The PRV47 can be installed in pressure reducing stations throughout all industries and provides sensitive and accurate control even when inlet pressure fluctuations or flow variations occur.

Stainless steel

1/4" and 3/8"

Threaded ISO 7 Rp or NPT

25 bar (steam), 31 bar (gases)

300°C

0.35 to 17 bar

1 or 1.1 Kvs (m³/h)

P7 Pressure Reducing Valve

The ADCA P7 series direct-acting, spring-loaded diaphragm sensing pressure reducing valves, are designed for use with steam, compressed air and other gases compatible with the materials of construction. They are suitable for pressure reducing stations where very small loads are involved. They are also specifically recommended to operate as pilot valves in combination with other pressure regulators.

Stainless steel

1/4" to 1/2" - DN 15

Female threaded ISO 7 Rp, ISO 228 or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

50 bar

80°C

0.2 to 15 bar

1.2 to 18 Kvs

P20D Pressure Reducing Valve

The ADCA P20D is a series of direct acting, spring-loaded, diaphragm sensing and balanced plug pressure reducing valves. These regulators are designed for use with compressed air, water and other gases and liquids compatible with the construction materials and valve design. They are suitable for pressure reducing applications at the point of use in laundry and dyeing machines, food industries, sterilizers, etc.

Stainless steel

1/4" to 1/2" - DN 15

Female threaded ISO 7 Rp, ISO 228 or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

14 bar

200°C

0.2 to 8 bar

1.2 to 18 Kvs

P20DS Pressure Reducing Valve

The ADCA P20DS is a series of direct acting, spring loaded, diaphragm sensing balanced plug pressure reducing valves. These regulators are particularly suitable for general purpose applications where low flow and high temperatures are involved and have been specially designed for use with steam.

Stainless steel

1/4"

Female threaded ISO 7 Rp, ISO 228 or NPT

220 bar

80°C

0.2 to 200 bar

0.043 to 0.62 Kvs

P20P Pressure Reducing Valve

The ADCA P20P is a series of direct acting, spring loaded, piston sensing pressure reducing valves. These regulators are designed for use with nitrogen, compressed air, water and other gases and liquids compatible with the materials of construction. They are suitable for general purpose pressure reducing applications such as instrumentation systems and industrial equipment where small loads and high pressures are involved.

Stainless steel

1/4" to 3/4" - DN 15 and DN 20

Female threaded ISO 7 Rp, ISO 228 or NPT

Flanged EN PN 40 to PN 250

Flanged ASME Class 150, 300 or 600

220 bar

80°C

3 to 200 bar

Up to 0.9 Kvs

PRV30 Pressure Reducing Valve

The ADCA PRV30SS is a series of direct acting, spring-loaded, diaphragm sensing and balanced plug pressure reducing valves. These regulators are designed for use with compressed air, water and other gases and liquids compatible with the construction materials and valve design. They are suitable for pressure reducing applications at the point of use in laundry and dyeing machines, food industries, sterilizers, etc.

Stainless steel

1/4" to 1" - DN 15 to 25

Threaded ISO 7 Rp or NPT

Flanged EN PN 25

Flanged ASME Class 150 or 300

11 bar

30°C

0.2 to 13 bar

Up to 0.1 Kvs

PRV31 Pressure Reducing Valve

The ADCA PRV31SS is a series of direct acting, spring-loaded, piston sensing and balanced plug pressure reducing valves. These regulators are designed for use with compressed air, water and other gases and liquids compatible with the construction materials and valve design. They are suitable for pressure reducing applications at the point of use in laundry and dyeing machines, food industries, sterilizers, etc.

Stainless steel

1/4" to 1" - DN 15 to 25

Threaded ISO 7 Rp or NPT

Flanged EN PN 25

Flanged ASME Class 150 or 300

20 bar

80°C

3 to 39 bar

Up to 1.1 Kvs

PRV41 Pressure Reducing Valve

The ADCA PRV41SS is a series of direct acting, spring loaded, piston sensing pressure reducing valves. These regulators are designed for use with nitrogen, compressed air, water and other gases and liquids compatible with the materials of construction. They are suitable for general purpose pressure reducing applications such as instrumentation systems and industrial equipment where small loads and high pressures are involved.

Carbon steel or stainless steel

1/2" to 1"

Female threaded ISO 7 Rp

Socket weld (SW) ASME

16 bar

80°C

0.21 to 17 bar

1.6 to 3.7 Kvs

PS46 Pressure Sustaining Valve

The ADCA PS46 series pressure sustaining valves are single seated, bellows sealed controllers that operate without auxiliary energy. These valves are designed for use with steam, compressed air, and other gases compatible with the construction. These valves are particularly suitable for maintaining the upstream pressure in all energy and process systems where pressures must be kept under control.

Carbon steel

DN 15 to DN 100

Flanged EN 1092-1 PN 16 or PN 40

Up to 19 bar

Up to 170°C

4.5 to 12.5 Kvs

PSW46B Pressure Sustaining Valve

The ADCA PSW46B series pressure sustaining valves are single seated, diaphragm or piston sensing proportional controllers that operate without auxiliary energy. Designed for use with water, compressed air and other liquids and gases compatible with the construction.

Carbon steel

DN 25 to DN 100

Flanged EN 1092-1 PN 16 or PN 40

Up to 19 bar

Up to 170°C

4.5 to 12.5 Kvs

PPS47 Pressure Sustaining Valve

The ADCA PS47 series pilot operated pressure sustaining valves are designed for use with steam, compressed air, nitrogen and other gases compatible with the construction materials. The PSV7 can be installed in pressure sustaining stations throughout all industries and provides sensitive and accurate control even when inlet pressure fluctuations or flow variations occur.

Carbon steel or stainless steel

1/2" to 2" - DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN PN 40

Flanged ASME Class 150 or 300

Socket Weld (SW) ASME B16.11

28 bar

250°C

0.07 to 17 bar

PS4 Pressure Sustaining Valve

The ADCA PS4 is a series of direct acting, spring loaded, diaphragm sensing pressure sustaining valves. These regulators are designed for use with compressed air, water and other gases and liquids compatible with the construction materials and valve design. They are suitable for pressure sustaining applications at the point of use in laundry and dyeing machines, food industries, sterilizers, etc.

Stainless steel

1/4" to 1/2" - DN 15

Female threaded ISO 7 Rp, ISO 228 or NPT

Flanged EN 1092-1 PN 40

Flanged ASME B16.5 Class 150 or 300

14 bar

200°C

0.2 to 8 bar

1.2 to 18 Kvs

BKR12 Blanketing Valve

The ADCA BKR12 is a series of tank blanketing valves designed for use with nitrogen, compressed air and other gases compatible with the materials of construction. These valves are suitable for maintaining a constant pressure in storage systems for volatile liquids, preventing evaporation losses and reducing the risk of fire or explosion.

Stainless steel

1/2" to 2" - DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN PN 40

Flanged ASME Class 150 or 300

10 bar

80°C

0.02 to 0.5 bar

BKV12 Blanketing Valve

The ADCA BKV12 is a series of tank blanketing valves designed for use with nitrogen, compressed air and other gases compatible with the materials of construction. These valves are suitable for maintaining a constant pressure in storage systems for volatile liquids, preventing evaporation losses and reducing the risk of fire or explosion.

Stainless steel

1/2" to 2" - DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN PN 40

Flanged ASME Class 150 or 300

10 bar

80°C

0.02 to 0.5 bar

RP45TW Pressure Reducing Station

The ADCA RP45TW is a parallel valve system designed for significant consumption variation. This pressure reducing station consists of two or more pressure reducing valves installed in parallel, with each valve sized for a specific flow range. This configuration ensures stable pressure control across a wide range of flow conditions.

Carbon steel or stainless steel

DN 50 to DN 200

Flanged EN 1092-1 PN 16 or PN 40

Up to 40 bar

Up to 250°C

0.2 to 18 bar

26.5 to 129.5 Kvs (m³/h)

Y162 Two-Way Control Valve

The ADCATrol Y162 is a series of single seated, two-way globe control valves designed for simple process engineering and industrial applications with non-critical operating conditions. These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

Y362 Two-Way Control Valve

The ADCATrol Y362 is a series of single seated, two-way globe valves designed for process engineering and industrial applications, where events such as erosion, cavitation or flashing may occur. These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

PY15 Pneumatic Control Valve

The ADCATrol PY15 is a series of single seated, two-way pneumatic cutoff globe valves with diaphragm actuator. These valves are suitable for use with the most common process fluids such as steam, water, apprehended water, air, neutral gases and oils.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

PPV15 Pneumatic Control Valve

The ADCATrol PPV15 is a series of single seated, two-way pneumatic cutoff globe valves with piston actuator. These valves are suitable for use with the most common process fluids such as steam, water, apprehended water, air, neutral gases and oils.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

PAV21 Pneumatic Angle Valve

The ADCATrol PAV21 is a series of pneumatic angle and gate valves with piston actuators. These valves are suitable for use with the most common process fluids such as steam, water, apprehended water, air, neutral gases and oils.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

EY15 Electric Control Valve

The ADCATrol EY15 is a series of single seated, two-way electric cutoff globe valves with electric actuator. These valves are suitable for use with the most common process fluids such as steam, water, apprehended water, air, neutral gases and oils.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

Kvs 4.8 to 52.6

PN 16

V303 Three-Way Control Valve

The ADCATrol V303 is a series of single seated, three-way globe control valves designed to ensure accurate control in mixing and diverting process engineering and industrial applications. These valves can be assembled with pneumatic, hydraulic or electric actuators, for modulating and shut-off control tasks.

Carbon steel and stainless steel

DN 15 to DN 100

Flanged EN PN 16 or PN 40

Kvs 4 to 160

V253 Three-Way Control Valve

The ADCATrol V253 is a series of three-way globe control valves designed to ensure accurate control in mixing or diverting general service applications. These valves can be assembled with pneumatic, hydraulic or electric actuators and used with the most common process fluids such as water, superheated water, thermal oil, steam, air, gas and other non corrosive fluids.

SG Iron

DN 15 to DN 150

Flanged EN PN 16 or PN 25

Kvs 4 to 330

PV403 Three-Way Control Valve

The PV403 control valves are three-way valve body for mixing service. The PA pneumatic actuator is rubber diaphragm and multi-springs. Its action can be DA – direct action (air to close) or RA – reverse action (air to open). The V403 valves have been designed to assure an accurate control in any process condition. Their wide application ranges allow the use of this valve with the most common process fluids such as water, superheated water, diathermic oil, steam, air, gas and other non corrosive fluids.

Carbon steel or stainless steel

DN 15 to DN 50

Flanged EN PN 16 or PN 40

Flanged ASME Class 150 or 300

Kvs 4 to 40

VPA26/2 Blowdown Valve

The VPA26/2 series of blowdown valves are specially designed for application on steam boilers, to remove sludge sediments which naturally settle on the bottom of the boiler. These intermittent valves operate manually or automatically with timed control. Available with diaphragm actuator and/or manual operation lever.

Carbon steel or stainless steel

3/4" to 2" – DN 20 to DN 50

Flanged EN PN 40

Flanged ASME Class 300

Kvs 6.3 or 16

VPC26 TDS Control Valve

The ADCATrol VPC26 is specially designed for TDS (Total Dissolved Solids) control applications in steam boilers.

Carbon steel or stainless steel

1/2" to 1-1/2" – DN 15 to DN 40

Flanged EN PN 40

Flanged ASME Class 300

Kvs 1.2 to 2.5

OVF40 Overflow Valve

The ADCATrol OVF40 is a series of single seated, two-way overflow valves with inline connections. These valves are mainly used in closed loop systems to ensure that a minimum flow is kept in the event that all connected consumers are in a low load condition or have simply shut down. In these scenarios, the valve will prevent problems such as pressure surges, pump cavitation and overheating.

Carbon steel or stainless steel

DN 15 to DN 80

Flanged EN PN 16 or PN 40

Kvs 5.2 to 89.7

PAR - PARF Pneumatic Actuator

PA series pneumatic multi-spring actuators with rolling diaphragm, offering decreased hysteresis and good linearity potential for operating range. Available in air to close and air to open versions, for modulating and cut-off services.

Aluminum and stainless steel

100 to 2500 cm²

Up to 6 bar

Up to 60 mm

200 Nm

PARM - PAMM Pneumatic Actuator

PA series pneumatic multi-spring actuators with rolling diaphragm, offering decreased hysteresis and good linearity potential for operating range. Available in air to close and air to open versions, for modulating and cut-off services.

Aluminum and stainless steel

100 to 2500 cm²

Up to 6 bar

Up to 30 mm

200 Nm

EL Electric Linear Actuator

Electric linear actuator EL series for modulating and open-close duty of control and regulating technology to operate control valves. The self-locking gear-system uses a fast and efficient device via opening and closing by an electronic valve to the end position, avoiding drifting the steps for the end position.

Up to 120 mm

24V AC/DC, 115V AC, 230V AC, 400V AC

IP 67

1.2 to 21.9 Nm

ELS Electric Linear Actuator

Electric linear actuator ELS series for modulating and open-close duty of control and regulating technology to operate control valves. The self-locking gear-system uses a fast and efficient device via opening and closing by an electronic valve to the end position, avoiding drifting the steps for the end position.

Up to 90 mm

24V AC/DC, 115V AC, 230V AC

IP 65

2.3 to 21.9 Nm

ELK Electric Linear Actuator

Electric linear actuator ELK series for modulating and open-close duty of control and regulating technology to operate control valves. The self-locking gear-system uses a fast and efficient device via opening and closing by an electronic valve to the end position, avoiding drifting the steps for the end position. In case of system failure, the electric linear actuator can spring-driven into the respective fail-safe position.

Up to 60 mm

24V AC/DC, 115V AC, 230V AC, 400V AC

IP 67

3.9 Nm (close), 2.6 Nm (open)

MAH Manual Linear Actuator

The ADCATrol MAH is a series of manual linear actuators with top mounted hand-wheel designed for use with modulating and cut-off valves. These actuators are particularly interesting for control applications where a precise manual adjustment of flow is required. These actuators can also be quickly assembled to control valves, whereas preventive maintenance operation while the original actuator is being carried out regulated.

Up to 60 mm

From -20°C to 80°C

20 to 42.9 Nm

TR Temperature Control Valve

The ADCA TR valves series are designed for direct-acting temperature control systems where the valve closes on temperature rise. They are single seated, in order to ensure an excellent tightness and are intended to be coupled with the thermostat models T.205 and T.405.

Stainless steel

1/2" to 1"

Female threaded ISO 7 Rp or NPT

16 bar

200°C

TR25/R Temperature Control Valve

The ADCA TR25/R valves series are designed for temperature control of cooling systems where the valve opens when the temperature rises. They are single seated, in order to ensure an excellent tightness, and are intended to be coupled with thermostat models T.205 and T.405.

Stainless steel

1/2" to 1"

Female threaded ISO 7 Rp or NPT

16 bar

200°C

BCS220 Blowdown Controller

The ADCATrol BCS220 is a blowdown controller specially designed for use with steam boiler. The device takes care of both TDS and intermittent blowdown control. TDS (Total Dissolved Solids) is controlled through measurement of the boiler water electrical conductivity and intermittent control is performed via a blowdown timer. The device utilizes a clear multifunction LCD to display measured conductivity, temperature, operational alarm status and provide an intuitive interface. The device is IP 66 rated NEMA 4X and can be panel, surface/wall and pipe mounted.

BCS220 – 90 to 265 V AC

BCS220-LV – 12 to 30 V DC

150 x 161 x 119 mm

IP 66 NEMA 4X

PCSI Pressure Transmitter

The ADCATrol PCSI is a series of pressure transmitters suitable for all industrial applications. It is specially designed to operate in severe conditions where high temperatures, pressure peaks, shock and vibrations are present. The PCSI is extensively robust and reliable, thanks to its use of SMD electronics and compact all stainless steel construction.

Male threaded ISO 228 G 1/2"

0 to 6 / 0 to 10 / 0 to 16 / 0 to 25 / 0 to 40 / 0 to 100 / 0 to 250 / 0 to 400 / 0 to 600 bar

< ±0.5% FS

< 1 ms

IP 65 / IP 67

4 to 20 mA (2 wire)

SPS21 Conductivity Probe

The ADCATrol SPS21 conductivity probe is typically used in steam applications to measure the conductivities of superheated boiler water, condensate or feedwater. The probe is used in conjunction with an ADCATrol BCS controller and a VPC series TDS blowdown control valve.

Male threaded ISO 7 R 1/2"

32 bar

230°C

IP 65

SPS33 Conductivity Probe

The ADCATrol SPS33 conductivity probe is typically used in steam applications to measure the conductivity of superheated boiler water, condensate or feedwater. The probe is used in conjunction with an ADCATrol BCS controller and a VPC series TDS blowdown control valve.

Male threaded ISO 228 G 1/2"

32 bar

230°C

IP 65

UD-720 Digital Panel Display

The ADCATrol UD-720 is a programmable digital panel display used for the measurement of standard sensor and analog signals applied in automation. It is ideally suited for use with our range of instrumentation such as pressure transmitter, temperature probes and others. The unit features a 24 V DC supply output for transmitters.

23 to 40 V AC/DC

101 x 48 x 96 mm

IP 65

UC-820 Digital Universal Controller

The ADCATrol UC-820 is a digital universal controller used in the assessment of industrial processes. It is ideally suited for use with our range of instrumentation, electric and pneumatic control valves and other electrical equipment.

24V AC/DC, 115V AC, 230V AC

96 x 96 x 130 mm

IP 65

PCLS Signal Converter

The ADCATrol PCLS is a compact device which converts a standard analog signal to a standard pneumatic signal. At the change-over between electrical controllers to pneumatic control valves, or from electrical measuring systems to pneumatic controllers. The PCLS is a force balance device, which converts a 4-20 mA input signal into a proportional linear 0.2 to 1 bar output signal, with a respective supply pressure of 1.4 to 5 bar.

Aluminum and polycarbonate

4 to 20 mA

0.2 to 1 bar (3 to 15 psi)

1.4 to 5 bar

-40 to 85°C

PPSS1 Pneumatic Positioner

The ADCATrol PPSS1 positioner requires an input signal of 0.2-1.0 bar (3-15 psi) for the proportional control actuator. The positioner compares the output signal from a controller with the position feedback and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.

0.2 to 1.0 bar (3 to 15 psi)

0.2 to 1.0 bar (3 to 15 psi)

1.4 to 7 bar

-40 to 85°C

PPSS6 Pneumatic Positioner

The ADCATrol PPSS6 positioner requires an input signal of 4-20 mA for the proportional control actuator. The positioner compares the output signal from a controller with the position feedback and varies a pneumatic output signal to the actuator accordingly. The actuator position is therefore guaranteed for any controller output signal and the effects of varying differential pressure.

4 to 20 mA

0.2 to 1.0 bar (3 to 15 psi)

1.4 to 7 bar

-40 to 85°C

SG IRON Air and Gas Float Trap

FA line of fully automatic ball float traps, manufactured in SG iron and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates, in various sizes, with different connections and multiple options to choose from.

SG Iron

Low and high-pressure applications

Wide range of flow rates

Various sizes available

Multiple connection options

CARBON STEEL Air and Gas Float Trap

FA line of fully automatic ball float traps, manufactured in carbon steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates, in various sizes, with different connections and multiple options to choose from.

Carbon Steel

Low and high-pressure applications

Wide range of flow rates

Various sizes available

Multiple connection options

STAINLESS STEEL Air and Gas Float Trap

FA line of fully automatic ball float traps, manufactured in stainless steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates, in various sizes, with different connections and multiple options to choose from.

Stainless Steel

Low and high-pressure applications

Wide range of flow rates

Various sizes available

Multiple connection options

CAD Compressed Air Automatic Drain Valve

The ADCA CAD compressed air automatic drain valve consists of a solid-state timer coupled to a solenoid valve. It is specially designed for automatic drainage of filters, separators, aftercoolers, dryers, receivers, drip legs and other compressed air system components where condensate and contaminants may collect. The drainage interval and discharge time can be adjusted according to the requirements.

3/8" and 1/2"

Female threaded ISO 7 Rp

CARBON STEEL Air and Gas Vent

AE line of air and gas vents for liquid systems, manufactured in carbon steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates, in various sizes, with different connections and multiple options to choose from.

Carbon Steel

Low and high-pressure applications

Wide range of flow rates

Various sizes available

Multiple connection options

STAINLESS STEEL Air and Gas Vent

AE line of air and gas vents for liquid systems, manufactured in stainless steel and designed for all types of low and high-pressure applications. The available models cover a wide range of flow rates, in various sizes, with different connections and multiple options to choose from.

Stainless Steel

Low and high-pressure applications

Wide range of flow rates

Various sizes available

Multiple connection options

VB21 - VB21M Vacuum Breaker

The ADCA VB21 vacuum breakers are simple and reliable devices that automatically relieve or "break" an unwanted vacuum condition, restoring the atmospheric pressure. These devices are particularly suitable for steam heated units of small and medium volume, such as heat exchangers, heating coils, calorifiers, jacketed kettles, steam boilers, etc.

Stainless steel

1/2" x 1/8"

VB21 – Female threaded ISO 7 Rp or NPT

VB21M – Male threaded ISO 228

13 bar at 400°C

21 bar at 220°C

VB17 Vacuum Breaker

The ADCA VB17 is a series of vacuum breakers designed to automatically relieve or "break" an unwanted vacuum condition. Applications include venting and vacuum limiting in pipelines, vessels, heat exchangers, autoclaves, steam boilers and other machines.

Stainless steel

1/2" to 2" – DN 15 to DN 50

16 bar

200°C

IS140 Pipeline Strainer

The ADCA IS140 is a series of Y strainers applicable in all types of steam, water, oil and air systems. Their purpose is to protect equipment, such as steam traps and regulating valves, from dirt and impurities which often cause damage and consequent downtime and energy loss.

Carbon steel and stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

60 bar

400°C

IS116 Pipeline Strainer

The ADCA IS116 forged steel Y strainers are applicable in all types of steam, water, oil and air systems. Their purpose is to protect traps, regulation valves, piping, etc. from dirt and impurities, which are often the causes of damage and consequent energy loss of fluid systems.

1/2" to 2" – DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN or ASME

Socket weld (SW) ASME B16.11

136 bar

425°C

IS147 Pipeline Strainer

The ADCA IS147 cast iron Y strainers are applicable in all types of steam, water, oil and air systems. Their purpose is to protect traps, regulation valves, piping, etc. from dirt and impurities, which are often the cause of damage and consequent energy loss of fluid systems.

Cast iron

DN 15 to DN 300

Flanged EN 1092-2 PN16

IS147 (EN) Pipeline Strainer

The ADCA IS147 cast steel T strainers are applicable in all types of steam, water, oil and air systems. Their purpose is to protect traps, regulation valves, piping, etc. from dirt and impurities, which are often the cause of damage and consequent energy loss of fluid systems.

Stainless steel or carbon steel

DN 15 to DN 100

Flanged EN 1092-2 PN 16, PN 25 or PN 40

IS147 (ASME) Pipeline Strainer

The ADCA IS147 cast steel T strainers are applicable in all types of steam, water, oil and air systems. Their purpose is to protect traps, regulation valves, piping, etc. from dirt and impurities, which are often the cause of damage and consequent energy loss of fluid systems.

Stainless steel or carbon steel

1" to 4"

Flanged ASME B16.5 Class 150 or 300

SW12 Sight Glass

The ADCA SW12 is a series of single window sight glasses specially designed for installation downstream of steam traps, to monitor their performance such as checking for live steam leakage or blockage. Such devices can also be used for monitoring flow conditions in other applications, particularly in pipelines with liquid medium.

1/2" to 2"

Female threaded ISO 7 Rp

12 bar

150°C

DW40 Sight Glass

The ADCA DW40 is a series of double window sight glasses specially designed for installation downstream of steam traps, to monitor their performance such as checking for live steam leakage or blockage. Such devices can also be used for monitoring flow conditions in other applications, particularly in pipelines with liquid medium.

Carbon steel

1/2" to 2" – DN 15 to DN 50

Threaded ISO 7 Rp or NPT

Flanged EN 1092-1 PN 16 or ASME B16.5 Class 150 or 300

60 bar

250°C

DW12 Sight Glass

The ADCA DW12 is a series of double window sight glasses specially designed for installation downstream of steam traps, to monitor their performance such as checking for live steam leakage or blockage. Such devices can also be used for monitoring flow conditions in other applications, particularly in pipelines with liquid medium.

Cast iron and stainless steel

DN 15 to DN 150

Flanged EN 1092-1/2 PN 16

16 bar

250°C

SCKI Sight Checker

The ADCA SCKI sight checkers function as both sight glasses and check valves. Such devices are designed for installation downstream of steam traps, to monitor their performance, while also working as reliable check valves to prevent condensate backflow.

Stainless steel

1/2" to 1"

Female threaded ISO 7 Rp or NPT

10 bar

150°C

RT25 Non-Return Valve

The ADCA RT25 all stainless steel disc check valves have a compact design and were specially designed for use with steam and hot condensate.

Stainless steel

1/4" to 2"

Female threaded ISO 7 Rp or NPT

21 bar

220°C

RD40 Non-Return Valve

The ADCA RD40 disc check valves have a compact design and are specially designed for use with steam and hot condensate.

Stainless steel

1/2" to 2"

Female threaded ISO 7 Rp or NPT

16 bar

200°C

M3B Isolation Valve

The M3B three-piece ball valves are reduced bore isolating valves designed for cut-off applications with steam, condensate and other gas or liquid media compatible with the construction.

Stainless steel

1/4" to 2"

Female threaded ISO 7 Rp or NPT

Socket weld (SW) ASME B16.11

100 bar

250°C

PN 160

M3H Isolation Valve

The M3H three-piece ball valves are full bore isolating valves designed for cut-off applications with steam, condensate and other gas or liquid media compatible with the construction.

Stainless steel

3/8" to 2"

Female threaded ISO 7 Rp or NPT

Socket weld (SW) ASME B16.11

100 bar

250°C

PN 160

M3SH Isolation Valve

The M3SH three-piece ball valves are full bore isolating valves designed for cut-off applications with steam, condensate and other gas or liquid media compatible with the construction.

Zinc plated carbon steel

1/4" to 2"

Female threaded ISO 7 Rp or NPT

Socket weld (SW) ASME B16.11

100 bar

250°C

PN 160

M3W1 / MW1 Isolation Valve

The M3W1 and MW1 wafer type ball valves are specially designed isolating valves for cut-off applications with steam, condensate and other gas or liquid media compatible with the construction.

Carbon and stainless steel

DN 15 to DN 150

Flanged EN 1092

16 bar

250°C

SM1 Spring Return Handle

Spring return handles, also called "dead man's handles" consist of an enclosed spring-loaded lever mechanism, which ensures safe operation when mounted on a control valve. This device ensures that the valve cannot be left open (or closed) as a powerful spring will place the valve in the fail-safe position as soon as the operator releases its handle.

Stainless steel

ISO 5211 mounting

NYMP Gauge Valve

The ADCA NYMP is a series of high pressure needle valves designed for gauge isolation in steam and other industrial fields. The NYMP valve is specially designed for use as a basic water supply valve, where the control is to focus on energy extraction as a TDS function as smart valve.

Stainless steel

Female threaded ISO 7 Rp

CCBB Gauge Valve

The ADCA CCBB gauge isolation valves are designed for protection of instrumentation such as pressure gauges, transmitters and sensors. The CCBB valve allows for isolation of the valve system for controlled instrument repair programs. The CCBB valve also allows for pressure measurement through the integrated test port which allows the equipment required for replacement or calibration procedures.

Carbon and stainless steel

Female threaded ISO 7 Rp

LCC-019 Level Gauge

The ADCA LCC-019 compact tubular level gauge valves are relatively short range level indicators. It includes all necessary valves to isolate the level in pressure vessels, which are often equipped with a single unit. Each pair of both types of valves also can be applied with the tools.

Stainless steel

Flanged connections

40 bar

200°C

POP Pressure Operated Pump

The ADCAMat POP (Pressure Operated Pump), fabricated in carbon steel (stainless steel on request), is recommended for the transfer of high-temperature liquids such as condensate, oils and others to higher elevation or pressure, especially where conditions involve closed vessels under vacuum or pressure. The pump can be operated by steam, compressed air or other gases, and can be used for lifting any kind of non-corrosive liquids.

Carbon steel and stainless steel

1/2" to 2" - DN 15 to DN 50

Flanged EN 1092

Flanged ASME B16.5 Class 150

Female threaded ISO 7 Rp

80 bar

180°C

Up to 2500 kg/h

POPS-K Packaged Pump Unit

The POPS-K packaged pump units can be used to lift and transfer condensate and other liquids in hazardous zones.

Condensate and liquid transfer in hazardous zones

POP-LC Low Capacity Pressure Operated Pump

The ADCAMat POP-LC low capacity pressure operated pump is recommended for the transfer of steam condensate, oils and other non-hazardous liquids (compatible with the construction) to higher elevation or pressure, especially where conditions involve closed vessels under vacuum or pressure. The pump can be operated using steam, compressed air or inert gas, and is manufactured in carbon steel or stainless steel.

Carbon steel and stainless steel

80 bar

180°C

Up to 250 kg/h

PPT14 Automatic Pump Trap

The ADCAMat PPT14 automatic pump trap is specially recommended when well conditions may occur due to poor return line condensate discharge capacity, caused by upstream insufficient pressure drop. The equipment combines in a single unit both a steam trap and a pressure-operated pump.

Carbon steel and stainless steel

1-1/2" and 2" to 4"

DN 40 x 3" and DN 50 x 40

Flanged EN 1092

Flanged ASME B16.5 Class 150

Female threaded ISO 7 Rp

PPT-K (Simplex) Packaged Pump Trap Unit

The ADCAMat PPT-K packaged pump trap unit is intended for lifting and transferring condensate in closed loop systems. This unit comprises the ADCAMat PPT14 pump trap, a receiver and all auxiliary components, offering a complete, tested and ready-for-connection package that reduces time, work and site costs. Two or more units can be connected in parallel to extend capacity beyond a single unit.

Carbon steel and stainless steel

DN 40 x 3" and DN 50 x 40

Flanged EN 1092

Flanged ASME B16.5 Class 150

Female threaded ISO 7 Rp

10 bar

180°C

ANST Automatic Pump Trap

The ADCAMat ANST automatic pump trap is specially recommended when well conditions may occur due to poor return line condensate discharge capacity, caused by upstream insufficient pressure drop. The equipment combines in a single unit both a steam trap and a pressure-operated pump.

Carbon steel and stainless steel

Flanged EN 1092

Flanged ASME B16.5 Class 150

Female threaded ISO 7 Rp

10 bar

180°C

S16 Humidity Separator

The S16 series centrifugal separators remove moisture from steam and compressed air pipelines. Steam or compressed air passes through the separator and, as a result of centrifugal forces, impacts and swirling effects, particles with heavier specific gravity such as water and oil droplets, moisture in suspension, dirt and scale are separated from the fluid. The condensate collected at the bottom is automatically drained by a suitable steam or compressed air trap (supplied separately).

S25 Humidity Separator

The ADCA S25 series centrifugal separators remove moisture from steam and compressed air pipelines. Steam or compressed air passes through the separator and, as a result of centrifugal forces, impacts and swirling effects, particles with heavier specific gravity such as water and oil droplets, moisture in suspension, dirt and scale are separated from the fluid. The condensate collected at the bottom is automatically drained by a suitable steam or compressed air trap (supplied separately).

SF251 Humidity Separator

The SF251/S series centrifugal separators remove moisture from steam and compressed air pipelines. Steam or compressed air passes through the separator and, as a result of centrifugal forces, impact and swirling effects, particles with heavier specific gravity such as water and oil droplets, moisture in suspension, dirt and scale are separated from the fluid. The condensate collected at the bottom is automatically drained by a suitable steam or compressed air trap (supplied separately).

Carbon steel

DN 15 to DN 100

Flanged EN 1092-1 PN16 or PN40

Flanged ASME B16.5 Class 150 or 300

40 bar

300°C

SH25 Humidity Separator

The SH25/S series horizontal centrifugal separators remove moisture from steam and compressed air pipelines. Steam or compressed air passes through the separator and, as a result of centrifugal forces, impact and swirling effects, particles with heavier specific gravity such as water and oil droplets, moisture in suspension, dirt and scale are separated from the fluid. The condensate collected at the bottom is automatically drained by a suitable steam or compressed air trap (supplied separately).

Carbon steel

1/2" to 6" - DN 15 to DN 150

Flanged EN PN 16 or PN 40

Flanged ASME Class 150 or 300

40 bar

300°C

PN 16 or PN 40

SC32 / SC132 Sample Cooler

The ADCA SC32 and SC132 sample coolers are specially designed to cool samples of boiler water or steam for analysis. Sample coolers prevent steam flashing-off from hot pressurized liquid samples, which can be dangerous and may result in incorrect samples. These devices may be used for boiler water analysis and other sampling or cooling applications compatible with the construction materials.

Stainless steel body and coil

Cooling water inlet/outlet: 1/2" on body (ISO 7 Rp or NPT)

Sample tube inlet/outlet: 5 mm

20 bar (body) 110 bar (coil)

120°C (body) 450°C (coil)

SC32F / SC132F Sample Cooler

The ADCA SC32F and SC132F sample coolers were specially designed to cool samples of boiler water or steam for analysis. Sample coolers prevent steam flashing-off from hot pressurized liquid samples, which can be dangerous and may result in incorrect samples. These devices may be used for boiler water analysis and other sampling or cooling applications compatible with the construction materials.

Stainless steel body and coil

Cooling water body inlet 1/2", outlet 5/4" (ISO 7 Rp or NPT)

Sample tube inlet/outlet: 5 mm

20 bar (body) 110 bar (coil)

120°C (body) 450°C (coil)

SC32B / SC132B Sample Cooler

The ADCA SC32B and SC132B sample coolers were specially designed to cool samples of boiler water or steam for analysis. Sample coolers prevent steam flashing-off from hot pressurized liquid samples, which can be dangerous and may result in incorrect samples. These devices may be used for boiler water analysis and other sampling or cooling applications compatible with the construction materials.

Stainless steel body and coil

Cooling water body inlet 1/2", outlet 1/2" (ISO 7 Rp or NPT)

Sample tube inlet/outlet: 5 mm

20 bar (body) 110 bar (coil)

120°C (body) 450°C (coil)

SC332 - SC532 Sample Cooler

The ADCA SC332, SC432 and SC532 sample coolers were specially designed to cool samples of boiler water or steam for analysis. Sample coolers prevent steam flashing-off from hot pressurized liquid samples, which can be dangerous and may result in incorrect samples. These devices may be used for boiler water analysis and other sampling or cooling applications compatible with the construction materials.

Stainless steel body and coil

Cooling water inlet/outlet: 1/2" on 2" (ISO 7 Rp or NPT)

Sample tube inlet/outlet: 10 mm O/D

20 bar (body) Up to 250 bar (coil)

100°C (body) Up to 550°C (coil)

DSH Direct Steam Humidifier

The ADCA DSH series of direct steam injection humidifiers are designed to ensure highly efficient and moisture-free steam injection in air ducts and AHU for humidification purposes. These units are completely manufactured from corrosion resistant stainless steel, and are available as plug-and-play packaged solutions or alternatively as individual components to be incorporated into humidification systems.

Stainless steel

1/2", 1" and 1-1/4"

Female threaded ISO 7 Rp or NPT

Flanged and special connections on request

SI20 Steam Injector

The ADCAMix SI20 is a series of direct steam injectors designed for low-noise heating of still or flowing mediums, inside basins and vessels.

3/4"

Female threaded ISO 7 Rp

Others on request

8.5 bar

180°C

SI21 Steam Injector

The ADCAMix SI21 is a series of direct steam injectors designed for rapid heating of still or flowing mediums, inside basins and vessels. Steam enters through the inlet connection, passes along the center of the device and mixes with the cool medium, which is drawn in through radial holes.

Austenitic stainless steel

1/2"

Female threaded ISO 7 Rp

Others on request

17 bar

95°C

PN 25

SI23 Steam Injector

The ADCAMix SI23 and SI24 are a series of direct steam injectors designed for rapid heating of still or flowing mediums, inside basins and vessels. Steam enters through the inlet connection, passes along the center of the device and mixes with the cool medium, which is drawn in through radial holes.

MX20 Steam-Water Mixer

The ADCAMix MX20 is a series of steam-water mixers designed to provide a cheap and instantaneous source of low pressure hot water, by using existing steam and cold water supplies. The mixer incorporates a safety device to ensure that live steam cannot be accidentally ejected even if the cold water supply fails. The water temperature at the outlet is easily controlled by using water and steam valves fitted at the inlets.

Stainless steel

3/4" x 3/4"

Female threaded ISO 7 Rp

10 bar

SG20 Water-Saving Gun

The ADCAMix SG20 series water-saving guns are specially recommended to be used along with the ADCAMix MX20 steam-water mixers. By using this gun, water and energy costs can be considerably reduced and contribute to environmental protection, avoiding the use of chemicals in the cleaning process.

1/2"

24 bar

ECRU Electric Condensate Recovery Unit

The ADCAMat ECRU series of electric condensate recovery units are recommended for the transfer of high-temperature water such as hot condensate, to a higher elevation or pressure. This condensate is usually used as boiler feedwater. The standard models are prepared for flows up to 30 m³/h, or higher on request. The units are composed of a horizontal condensate vessel (receiver), a metallic support frame, electric pumps, level controls, valves, prewired control panel and pipework for connections between the different elements.

ECRUV Electric Condensate Recovery Unit

The ADCAMat ECRUV series of electric condensate recovery units are recommended for the transfer of high-temperature water such as hot condensate, to a higher elevation or pressure. This condensate is usually used as boiler feedwater. The standard models are prepared for flows up to 4 m³/h. The units are composed of a vertical condensate vessel (receiver), a metallic support frame, electric pump, level controls, valves, prewired control panel and pipework for connections between the different elements.

PWHU Packaged Water Heating Unit

The ADCAThern PWHU packaged water heating units are designed for instant hot water heating in a safe and efficient way, using steam as primary fluid. Each system is built to meet application and space requirements in a compact skid package, ready for connection into the system, reducing on-site labour and disruption time.

FRECO Flash Steam Heat Recovery Unit

The ADCAThern FRECO flash steam heat recovery units are designed to facilitate heat recovery from flash steam, condensate or both. The system is specially recommended for heating a continuous flow of fluid, such as make-up water to a boiler feed water system. Non-continuous flow applications may require additional recirculation, relief valves, or other devices to avoid system damage due to overheating and consequent overpressure.

STS Heat Exchanger

The ADCA STS series steam to water shell and tube heat exchangers are shorter and lighter than alternative shell and tube exchangers manufactured with smooth pipes. The use of extended low fin tube has the advantage that it can improve the external surface and thermal performance.

Stainless steel

Flanged or threaded, according to EN or ASME standards

16 bar

230°C

STH Heat Exchanger

The ADCA STH series steam to water shell and tube heat exchangers are shorter and lighter than alternative shell and tube exchangers manufactured with smooth pipes. The use of extended low fin tube has the advantage that it can improve the external surface and thermal performance.

Carbon steel and stainless steel

Flanged or threaded, according to EN or ASME standards

16 bar

230°C

STV Heat Exchanger